Premium Quality Aluminium Tapes

Diamond Coatings offer a range of premium quality Aluminium Tapes that stand as a testament to their commitment to excellence.

ITO (Indium Tin Oxide) is well known for its use in coating glass but due to modern advancements, ITO can also be used to coat plastic substrates such as acrylic, polycarbonate or polyester (PET) film, to meet the demands of a wider variety of applications across many industries.

Polyester film is composed of polyethylene terephthalate (PET) and is a high-performance, clear thermoplastic. ITO Polyester film has ideal mechanical properties for processing, such as vacuum coating and laminating.

Choosing to use ITO polyester film over other thermoplastics provides an array of superior properties. PET film has:

Applications of ITO Coated PET Films

The properties that using ITO plastic films provide make it the perfect choice for certain product requirements and has resulted in its widespread use in many areas and applications.

As ITO PET film coatings can withstand harsh environments and temperatures, ITO thin film strain gauges can be used in extreme environments such as gas turbines and the engines of jets and rockets.

Another example of ITO plastic films within the aerospace industry, is that of ITO films use in defrosting an aircraft’s windshield. This is achieved by applying voltage which generates heat, that can be conducted by the indium tin oxide coating.

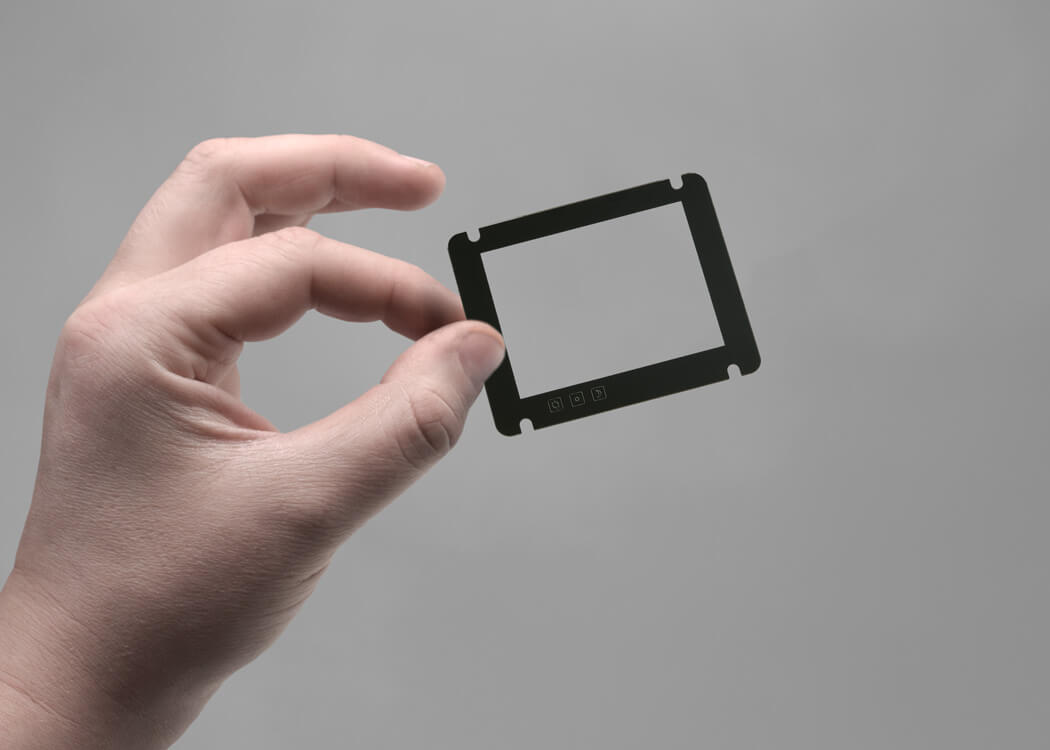

Resistive touchscreens are the most common type of touchscreen in use and these screens are usually made up of two layers with a small gap between them. The outer layer of the screen is usually a clear polycarbonate layer while the inside layer is rigid and often made of glass or PET film.

ITO coated PET films are often chosen to meet specifications for applications due to their processing tolerance, with their suitable for engineering. Such applications include photovoltaic back-sheets, tamper evident, protective, antimicrobial and packaging films, amongst others.

Another advantage of ITO coated polyester films is that they are conductive, yet still transparent. These properties allow for use in electroluminescent lamps, electrophoretic displays and EMI/RFI Shielding, and more.

ITO Coated PET Film Supplier

With a standard 175-micron thickness, Diamond Coatings’ ITO polyester film is available in sheets (600 mm x 457 mm standard sheet size), rolls (maximum width: 600 mm; lengths up to 100 m) and laser cut shapes. Standard sheet resistances include 18, 50 and 100 ohms/sq.

To aid handling and fabrication, Diamond Coatings ITO polyester film is available with protective films on both surfaces.

If you require any more information about our ITO coated PET film range contact the team at Diamond Coatings to discuss your specifications or find out more about what we provide.

Diamond Coatings offer a range of premium quality Aluminium Tapes that stand as a testament to their commitment to excellence.

Whether it’s display screens, architectural windows, or precision optics, anti-reflection coated screens reduce reflections and improve visual comfort

Whether it’s in automotive applications, medical equipment, or any environment where precise visibility is a must, anti-fog solutions have become indispensable

Have you ever wondered how outdoor touch displays function, especially in the face of the unpredictable elements?

If you are interested in any of our products or services, please use the contact form or give us a call, we will be happy to discuss how we may be able to help you.